Custom Molded Graphite Seals

Custom Molded Graphite Seals

Graphite Seals: Superior in High Temperature Applications

- The Jim Ray Company innovatively created the Graphite Seal for the Oil and Gas industry in the 1980s

- These seals are primarily used in as lockscrew packing in wellheads and stem packing in ball and gate valves

- The Jim Ray Company can tailor a graphite seal solution for your company based on its UltraBraid Line found below

- With its superior performance in high temperatures, Graphite Seals are much more reliable than competing seals

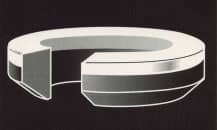

UltraBraid 940

Valve Packing. Available with stainless steel, Monel®, Inconel®, or other cap materials. The cap reduces the extrusion gap and centers the stem.

UltraBraid 950

Double capped lockscrew packing set with a friction reducing coating. Capable of sealing to 37,000 P.S.I. and 1,000° F plus.